Innovative Shrink Machines

In the ever-evolving world of tooling

technology, one name stands out for its innovative solutions and commitment to

quality – Bilz. As leading manufacturer in the industry, we have consistently

pushed the boundaries with our cutting-edge shrink machines that cater to

various customer requirements.

Introduction

In the ever-evolving world of tooling technology, one name stands out for its innovative solutions and commitment to quality – Bilz. As leading manufacturer in the industry, we have consistently pushed the boundaries with our cutting-edge shrink machines that cater to various customer requirements.

The Starter Range: Economical Introduction to Shrink Technology

For those looking to introduce themselves to shrink technology without breaking the bank, Bilz offers a range of manual machines with air cooling. These starter models are perfect for businesses that require basic tooling solutions and have limited budgets. With an approximate cooling time of 300 seconds, these machines provide a cost-effective entry point into the world of shrink technology. Additionally, they can be fitted with coolers as an option to further enhance their capabilities.

Click here to browse available models.

The Allrounder Range: Efficient Shrinking with Integrated Liquid Cooling

As businesses grow and require more efficient tooling solutions, Bilz offers its all-around range of manual machines with liquid cooling. These models boast a cooling time of just 30 seconds, ensuring that tools are always ready for use in the shortest possible time. The integrated liquid cooling system allows for shrinking and cooling to be carried out in one position without requiring any physical contact with the hot chuck. This feature not only increases safety but also maintains concentricity by providing a uniform cooling process.

Click here to browse available models.

The Professional Range: Fully Automatic Machines with Liquid Cooling and Geometry Independent Drying

For businesses that demand maximum operator safety, efficiency, and precision, Bilz's professional range of fully automatic machines is the ideal choice. These high-performance models feature liquid cooling and drying processes to guarantee a seamless shrinking experience. The fully automated process ensures that the heated shrink chuck is lowered directly into the cooling position following the shrinking procedure without any risk of operator contact with hot surfaces. This not only reduces the likelihood of burning but also maintains consistent concentricity for optimal tool performance.

Click here to browse available models.

Starter Range

Economical Introduction to ThermoGrip Shrink Technology

The Starter range is ideal choice for businesses looking to introduce themselves to shrink technology without breaking the bank, Bilz offers a range of manual machines with air cooling. These entry-level models are perfect for businesses that require basic tooling solutions and have limited budgets. With an approximate cooling time of 300 seconds, these machines provide a cost-effective entry point into the world of shrink technology. Additionally, they can be fitted with liquid coolers as an option to further enhance their capabilities.

Allrounder Range

Efficient Shrinking with Integrated Liquid Cooling

The All-around range of manual machines with liquid cooling is perfect choice for growing bussinesses requiring efficient tooling solutions. These models boast a cooling time of just 30 seconds, ensuring that tools are always ready for use in the shortest possible time. The integrated liquid cooling system allows for shrinking and cooling to be carried out in one position without requiring any physical contact with the hot chuck. This feature not only increases safety but also maintains concentricity by providing a uniform cooling process.

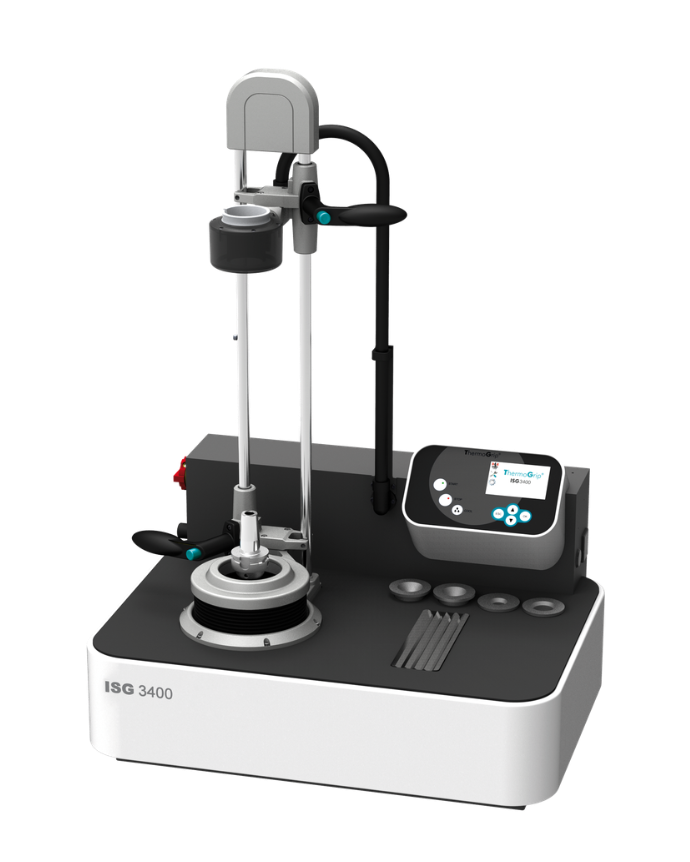

Professional Range

Fully Automatic Machines with Liquid Cooling and

Geometry Independent Drying

The Professional range of fully automatic machines offers maximum safety, efficiency, and precision. These high-performance models feature liquid cooling and drying processes to guarantee a seamless shrinking experience. The fully automated process ensures that the heated shrink chuck lowers directly into the cooling position after the procedure, avoiding any risk of operator contact with hot surfaces. This not only reduces the chance of burning but also maintains consistent concentricity for optimal tool performance.

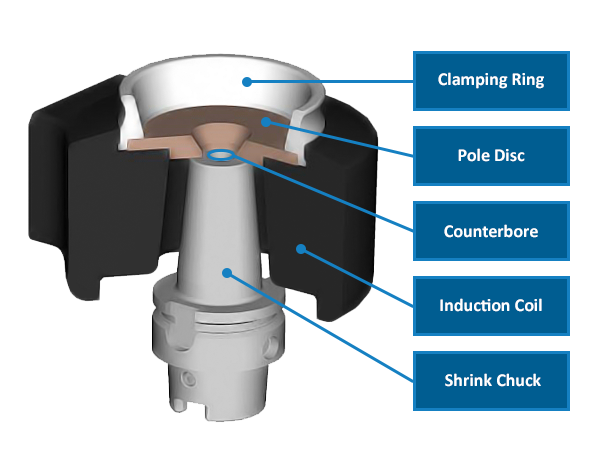

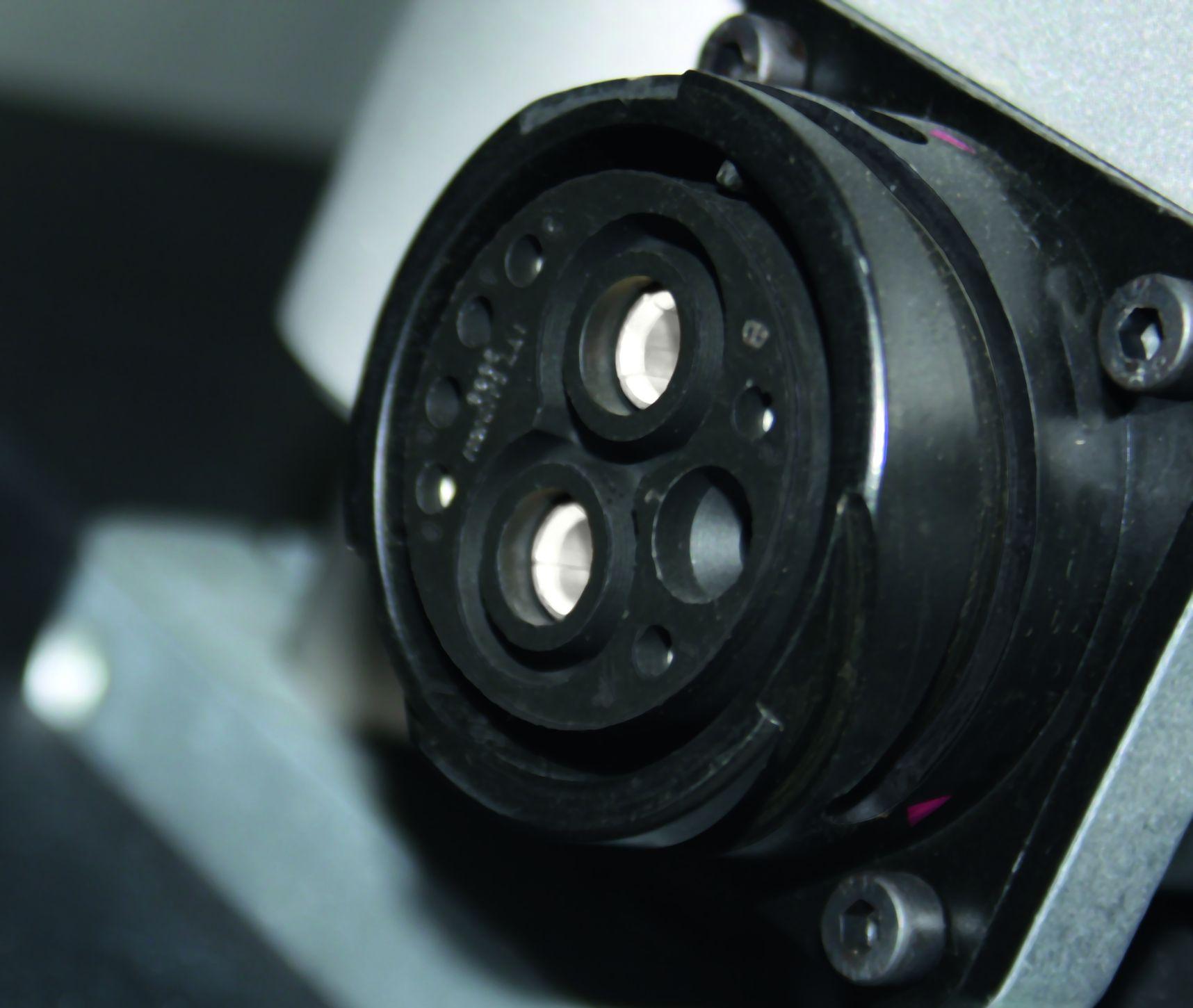

Advantages of Pole Discs

The pole discs developed by Bilz are a crucial component in shrink technology, playing an essential role in focusing magnetic flow at the optimal point of a heated chuck. These discs offer numerous advantages for the process, significantly improving overall performance. As a result, this innovative technology has become the industry standard.

Enhanced Safety: Pole discs block magnetic waves around the tool, preventing it from overheating and ensuring that users can safely handle it. This safety feature, combined with Bilz's patented counterbore design, contributes to smooth shrinking in and out without risking the tool getting stuck inside the chuck.

High Shrinking Performance: Pole discs control magnetic flow used for heating the shrink chuck by focusing it at a smaller area, reducing energy consumption and heat generation. This results in an extended lifespan of the shrink chuck while lowering overall energy usage.

Easy Handling & Maintenance: Pole discs are easy to handle and maintain, with no need for special cleaning agents or procedures. They can simply be wiped clean after use, reducing downtime and increasing productivity.

Bilz "Cool Down" Technology

Bilz "Cool Down" technology ensures a fully automated shrinking, cooling and drying process, providing enhanced safety, efficiency and precision.

Automated Process: The heated shrink chuck is lowered directly into the cooling position following the shrinking procedure without any risk of operator contact with hot surfaces. This reduces the likelihood of burning and maintains consistent concentricity for optimal tool performance.

Temperature, Time & Cooling Controls: The machine automatically controls the temperature, time, and cooling process to prevent overheating or damage to shrink chucks. This ensures that tools are always cooled down properly before use and chuck's lifespan is preserved.

Liquid Cooling via a Cooling Tower Principle: By using this innovative liquid cooling method, non-production times are minimized as the cooling process is completed within 20 seconds.

No Dependency on Contour: The cooling system doesn't rely on contours, so it can be used with different chuck geometries without requiring additional equipment. This eliminates potential damage to cutters caused by coolant caps and ensures a clean workspace.

Heating & Cooling in One Position: By heating and cooling the shrink chucks in one position, operators can avoid moving hot tools, reducing safety risks and maintaining an organized work area.

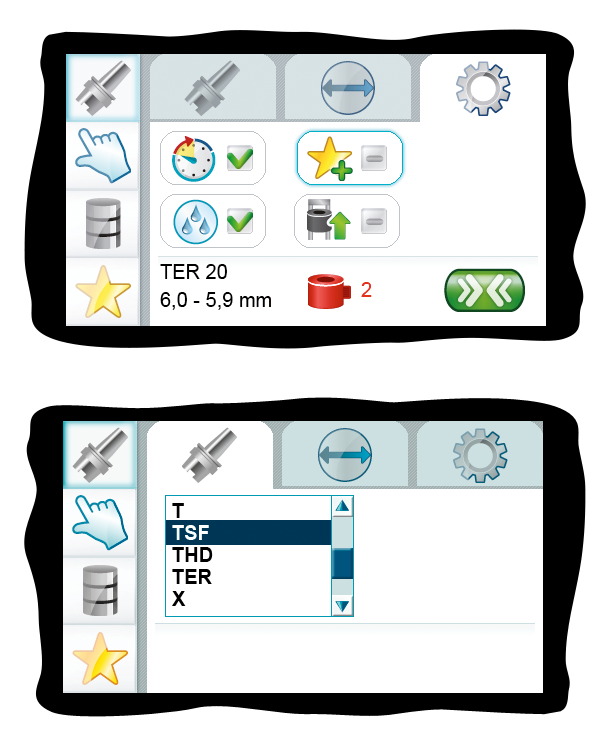

Operation of Shrink Machine with Graphical User Interface (GUI)

The Graphical User Interface (GUI) is used in most of our shrink machines for enhanced usability, versatility and efficiency. This control panel offers several advantages over previous numerical design:

Intuitive Operation: The graphics-based system allows for more intuitive operation, making it easier to understand and navigate through the various functions.

Self-Writing: With a language-independent design, GUIs can be easily understood by users of different languages without any translation issues.

Increased Perceptibility: Graphics are more perceivable than text, allowing for better visual representation and understanding of the processes involved in shrinking.

Pleasant Appearance: The visually appealing design of GUIs enhances user experience and overall satisfaction with the machine's operation.

Favorites List & Previous Entries: The GUI offers maximum productivity through a favorites list and allows users to call up previous entries, streamlining workflows and increasing efficiency.

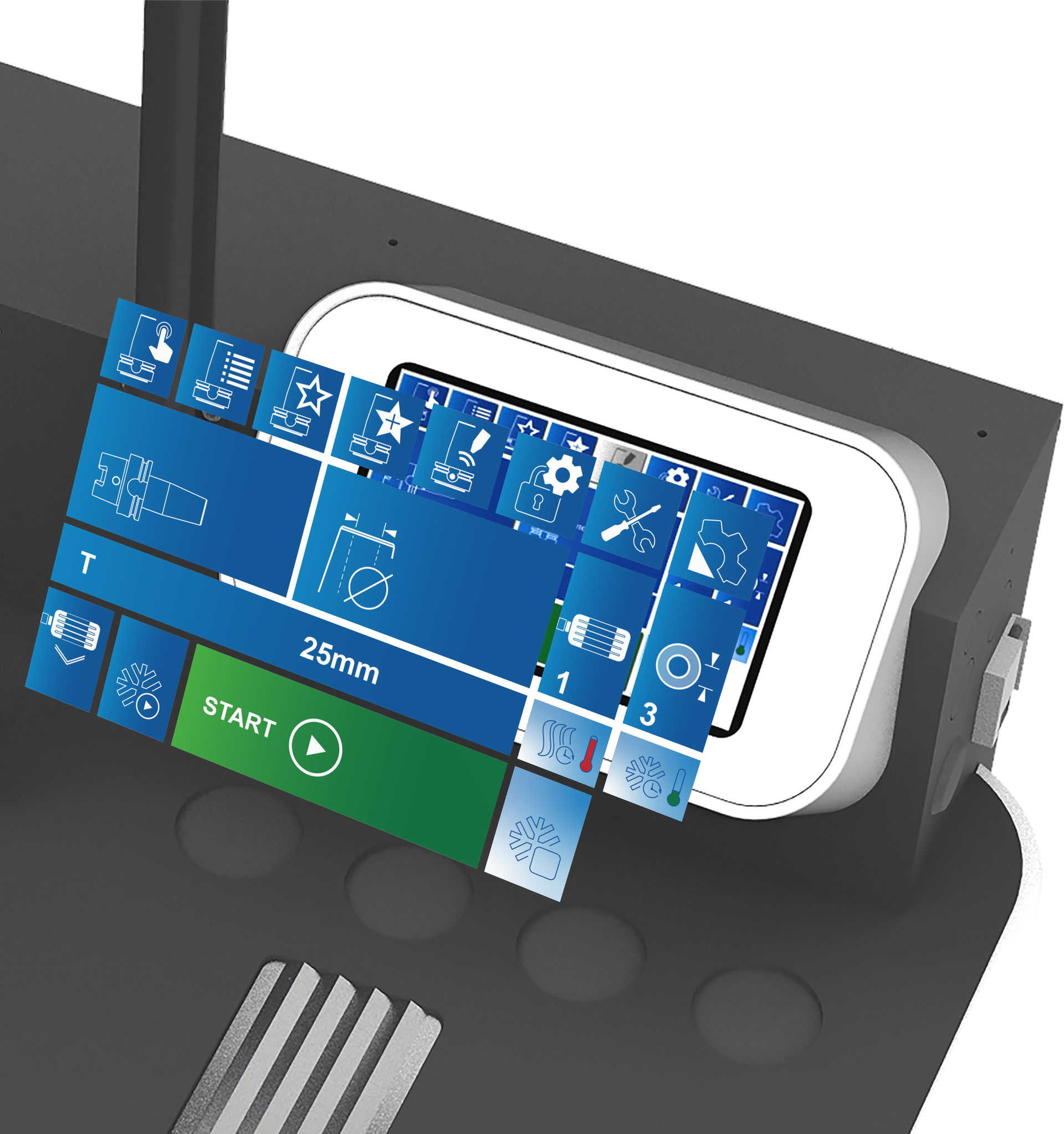

The new Touchscreen Technology

The new touch screen technology introduced by Bilz provides enhanced usability, efficiency, and precision in shrinking processes.

Automatic Mode vs Manual Mode: Users can choose between automatic or manual mode depending on their preferences and requirements. In the automatic mode, the entire shrink process is carried out securely, easily, and quickly with just three clicks.

Customizable Parameters: Individual shrinking parameters can be set according to specific needs, ensuring optimal results for each tool. The system finds the right parameters by reading data chips or using optical codes.

Favorites List & Previous Entries: The touch display offers maximum productivity through a favorites list and allows users to call up previous entries, streamlining workflows and increasing efficiency.

Expert Customization Options: Experts can define and store their own processes in the interface, enabling personalized shrinking techniques tailored to specific applications or materials.

Convenient Touch Display Navigation: The touch display features a user-friendly graphic menu with eight clearly structured main menu items for easy access and operation during the entire process.

Parameter Mode

Users can choose between automatic mode or manual mode depending on

their preferences and requirements.

Library*

The system allows selection of individual shrink parameters, such as

those required for special geometries.

Quick Adjustments

Easy activation/deactivation of hold or hold-back time is possible with

this feature.

Chip System*

Shrinking can be done using data carriers (optional), where the machine

imports shrink parameters from a data chip, enabling fully automatic operation.

Favourites List & Previous Entries

The touch display provides productivity through a favorites list and allows users to access previous entries for streamlined workflows.

Tool Setup*

Users can define their own processes in the

interface, tailoring shrinking techniques according to specific applications or

materials.

Machine Settings

Configuration of the machine parameters.

Infopoint

In this mode, users can easily turn off the machine or perform various operational and maintenance checks for enhanced functionality and efficiency.

* Optional feature, activation required. Please contact us for more info.

Additional Features

Quick Change System for ISG 3400 Series

The quick change system, which comes as standard in all 3400-WS series shrink machines, is a highly beneficial feature that enables users to easily swap out the coil on a plug and play basis if they need to accommodate larger tool shank diameters.

Plug 'n Play Coils for Enchanced Flexibility

In combination with our Quick Change System, Bilz offers a selection of easily interchangeable coils to meet every customer's needs. The ISGS3400-2 - Large Induction Coil allows you to shrink tool shank diameters from 32mm - 50mm. The ISGS3400 - Flexible Induction Coil can be adjusted to accommodate various tool dimensions, ensuring precise and efficient results for different applications. This solution eliminates the need for using a pole discs. Finally, the ISGS3400-NI - Stainless Induction Coil has specifically adapted geometry for optimal heat transfer to stainless shrink fit chucks. It's important to note that non-standard pole discs are required with stainless coil.

Click here to read more.

Tool Data Storage Chips (TDSc)

The optional TDSc (Tool Data Storage Chip) technology enhances the efficiency and accuracy of shrink processing by allowing users to input tool parameters directly into the machine, automating the process with consistent results. The data chips store essential information about tools, increasing productivity and reducing errors during manual entry. Users can define custom processes for specific applications or materials, ensuring optimal performance in various scenarios.

The

system supports both Balluff and Siemens data chips, for more informationclick here.

5108649 - ISGZ3410-BIS-C / Balluff Chip Reader

5097703 - ISGZ3410-BILZ-ID / Siemens Chip Reader

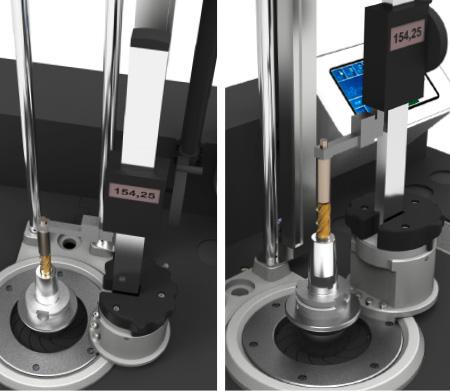

Cost-Effective Length Presetting

The ThermoGrip® Length Presetting feature offers an affordable entry point into presetting while providing significant benefits in terms of efficiency and versatility. The length within the tool holder can be set independently of the clamping device, allowing for greater flexibility during shrinking process.

Due to its simple handling, the feature can save time during production processes by guaranteeing process security in terms of dimensional accuracy at the length presetting stage. This results in reduced costs and improved overall efficiency within your manufacturing operations.

Click here to read more.

Inverse Shrink Kit

The Bilz Invers Shrink Kit is designed to provide a versatile solution for handling larger tool diameters during the shrinking process. The kit includes various components that work together to ensure optimal performance and efficiency in your manufacturing operations. Imortant to note, inverse shrink kit requires two-piece pole discs.

Click here to read more.